| Material Category | |

|---|---|

| Material | |

| Stock or Special Order | |

| Type of Tape | |

| Adhesive | |

| Produced as | |

| Roll Widths | |

| Reach / RoHS | |

| Made in: | |

| Test Methods: | |

| Disclaimer a: | Technical data presented above is the foam/material prior to the adheisve. |

| Disclaimer b: | End user is responsible for determining the suitability of the product to application. |

| Terms and Conditions | |

| Sku |

High Bond Tape – Clear – PHB1000

High Bond Clear Double-Sided Tape.

Transparent direct acrylic foam with an industry leading adhesive bond. Great for most high bond glass, signage, high and medium surface energy applications.

Adhesive: high-tack permanent acrylic pressure sensitive adhesive (PSA) on both sides with easy-to-use release liner.

Primer available for low surface energy applications.

Also available in gray, our PHB5100 series.

Produced in rolls, sheets, pre-cut (digital & die-cut) shapes, spools, and other customizable options.

High Bond Clear Double-Sided Tape.

Transparent direct acrylic foam with an industry leading adhesive bond. Great for most high bond glass, signage, high and medium surface energy applications.

Adhesive: high-tack permanent acrylic pressure sensitive adhesive (PSA) on both sides with easy-to-use release liner.

Primer available for low surface energy applications.

Also available in gray, our PHB5100 series.

Produced in rolls, sheets, pre-cut (digital & die-cut) shapes, spools, and other customizable options.

Request For Quote

You may also like…

-

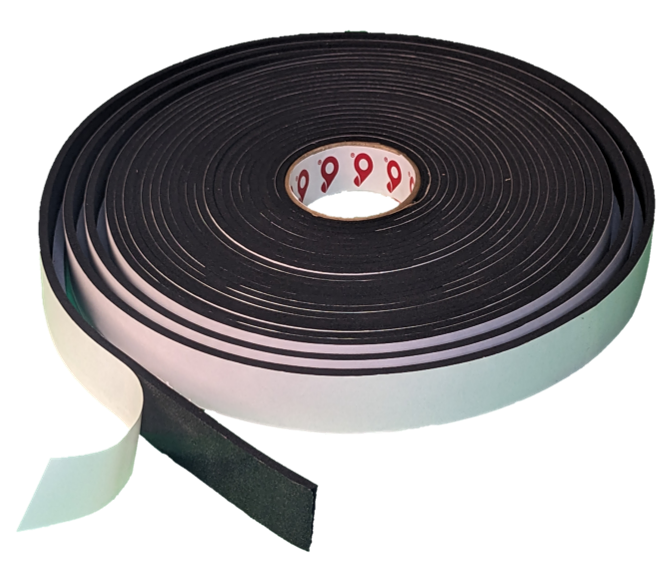

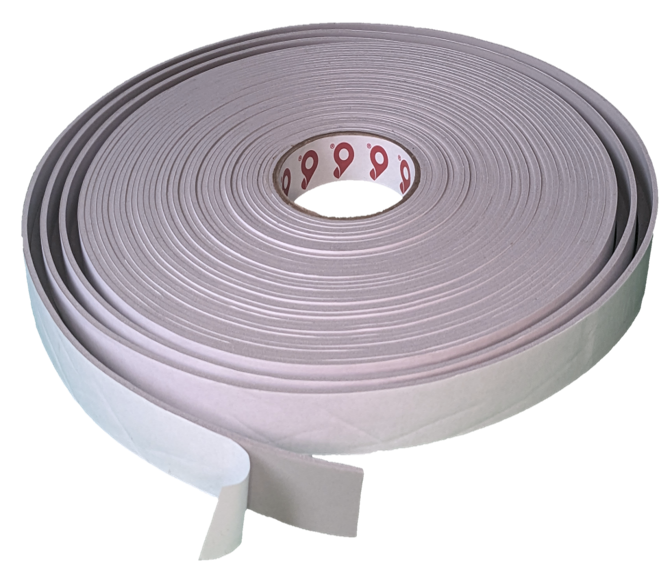

Polyethylene Foam Tape- Soft – P4200 – Double Sided

Polyethylene Double Sided Foam Tape. Closed cell soft, white or black, with a smooth surface. Double-sided cross-linked PE foam with… -

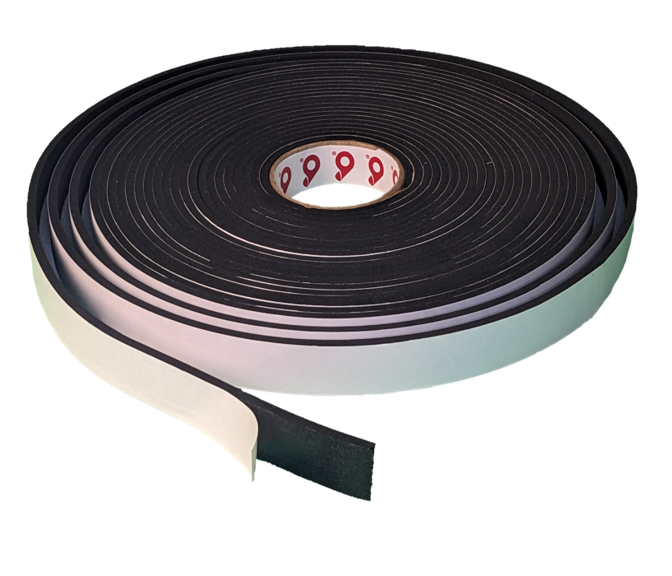

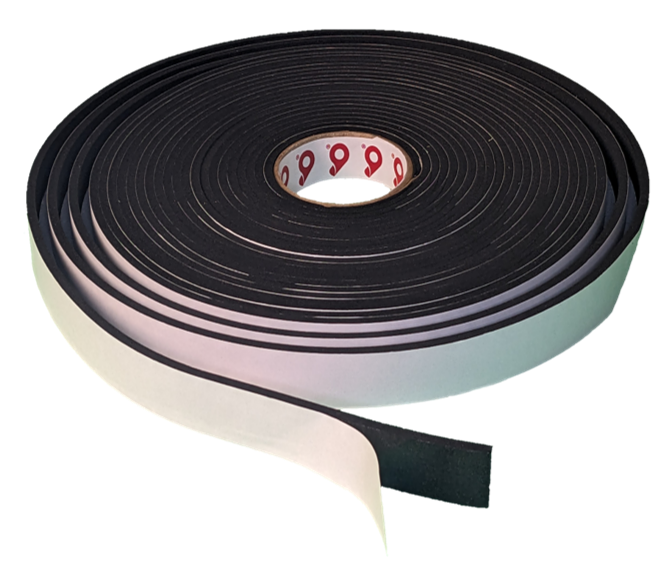

Neoprene / EPDM Blend Foam Tape – Soft – P8200DC – Double Sided

Neoprene / EPDM blend Double Sided Foam Tape. Closed cell soft, black, with a smooth surface. Durable double sided PSA… -

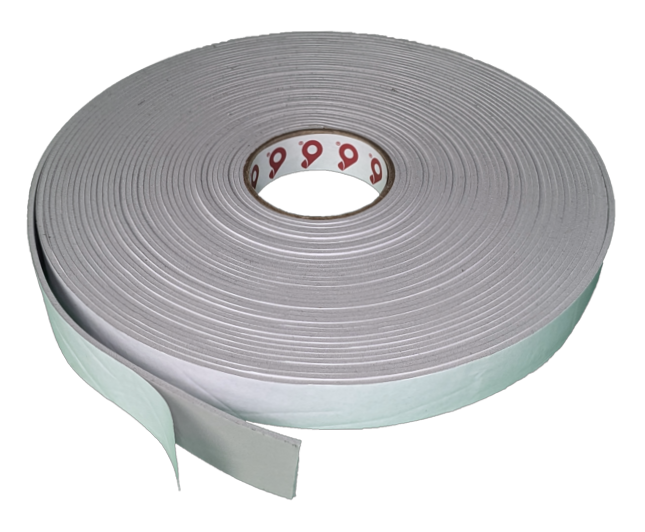

High Bond Tape – Gray – PHB5100

High Bond Double Sided Tape. Gray. Solid acrylic core tape with an industry leading adhesive bond. Great for most exceptional… -

Polyethylene Foam Tape – Soft – P4300 – Double Sided

Polyethylene Double Sided Foam Tape. Closed cell soft, white or black, with a smooth surface. Double-sided cross-linked PE foam with…