| Material Category | |

|---|---|

| Material | |

| Cell Structure | |

| Stock or Special Order | |

| Type of Tape | |

| Adhesive | |

| Thickness | |

| Produced as | |

| Roll Widths | |

| Softness | |

| Color | |

| Texture | |

| Durability | |

| Material Price | |

| Foam High Temperature Rating | |

| Foam Low Temperature Rating | |

| Outdoor | |

| UV Exposure | |

| Adhesive Temperature Range | |

| ASTM D1056 Classification | |

| ASTM D 1056-67 (outdated) | |

| Compression Deflection | |

| Durometer Shore | |

| Density | |

| Tensile Strength | |

| Compression Set | |

| Elongation | |

| UL Rating | Yes, UL 94 HF-1, UL 508, UL 50E, UL 157 |

| Flammability | |

| NEMA Rating | NEMA 1, NEMA 2, NEMA 3, NEMA 3R, NEMA 3RX, NEMA 3S, NEMA 3SX, NEMA 3X, NEMA 4, NEMA 4X, NEMA 5, NEMA 6, NEMA 6P |

| Additional Specs | ASTM D1149-91, ASTM D1171-94, CHRYSLER MSAY 527, GM4486P, GM6086M, NEMA 4X |

| Reach / RoHS | |

| Made in: | |

| Test Methods: | |

| Disclaimer a: | Technical data presented above is the foam/material prior to the adheisve. |

| Disclaimer b: | End user is responsible for determining the suitability of the product to application. |

| Terms and Conditions | |

| Sku |

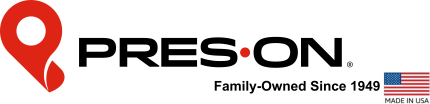

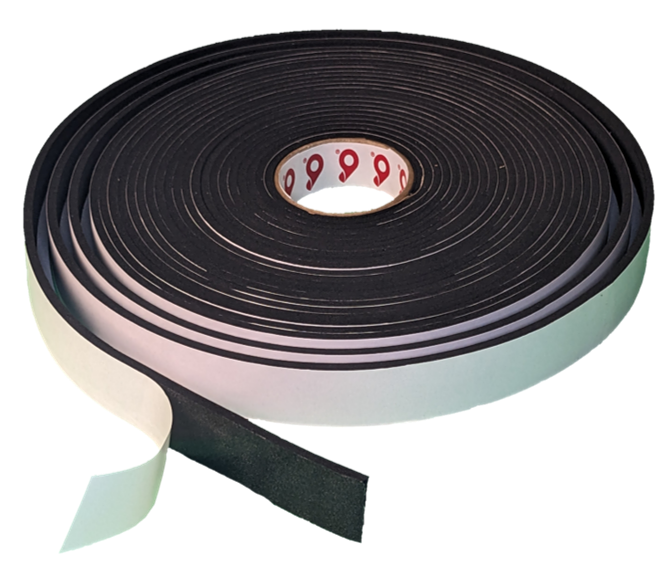

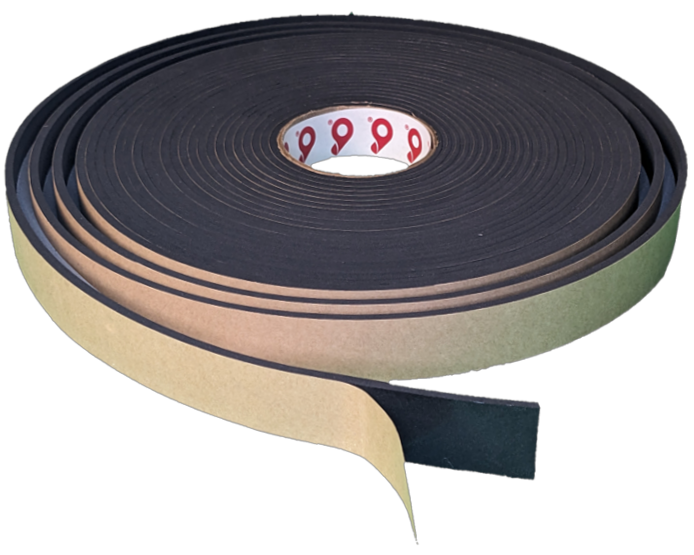

Neoprene / EPDM Blend Foam Tape – Soft/Medium – P8100UL

Neoprene / EPDM blend Foam Tape. Closed cell soft, black, with a smooth surface. Also known as Blended EPDM foam tape.

Durable industrial strength, UL listed foam with an industry leading adhesive bond. Great for most HVAC, enclosure, construction, all gasket applications.

Adhesive: Pres-On’s superior direct wet coat high-tack permanent rubber pressure sensitive adhesive (PSA) on one side with easy-to-use release liner.

Also available as a special order using our permanent high tack acrylic adhesive, double side, or without adhesive.

Produced in rolls, sheets, pre-cut (digital & die-cut) shapes, spools, and other customizable options.

Learn about “Pres-On’s Superior Wet-Coat Adhesive”

Neoprene / EPDM blend Foam Tape. Closed cell soft, black, with a smooth surface. Also known as Blended EPDM foam tape.

Durable industrial strength, UL listed foam with an industry leading adhesive bond. Great for most HVAC, enclosure, construction, all gasket applications.

Adhesive: Pres-On’s superior direct wet coat high-tack permanent rubber pressure sensitive adhesive (PSA) on one side with easy-to-use release liner.

Also available as a special order using our permanent high tack acrylic adhesive, double side, or without adhesive.

Produced in rolls, sheets, pre-cut (digital & die-cut) shapes, spools, and other customizable options.

Learn about “Pres-On’s Superior Wet-Coat Adhesive”

Request For Quote

You may also like…

-

EPDM – Medium Foam Tape – P9100

EPDM Foam Tape. Closed cell medium, black, with a smooth surface. Great quality with excellent UV and temperature resistance foam… -

Neoprene / EPDM Blend Foam Tape – Soft – P8200DC – Double Sided

Neoprene / EPDM blend Double Sided Foam Tape. Closed cell soft, black, with a smooth surface. Durable double sided PSA… -

Neoprene Foam Tape – Soft – NE4100

100% Neoprene Foam Tape. Closed cell soft, black, with a smooth surface. Best quality neoprene foam with an industry leading… -

Neoprene / EPDM Blend Foam Tape – Firm – P8300

Neoprene / EPDM blend Foam Tape. Closed cell firm, black, with a smooth surface. Firm with durable industrial strength foam…