| Material Category | |

|---|---|

| Material | |

| Cell Structure | |

| Stock or Special Order | |

| Type of Tape | |

| Adhesive | |

| Thickness | 1/32", 1/16", 1/8", 3/16", 1/4", 5/16", 3/8", 1/2", 3/4", 1" |

| Produced as | |

| Roll Widths | |

| Softness | |

| Color | |

| Texture | |

| Durability | |

| Material Price | |

| Foam High Temperature Rating | |

| Foam Low Temperature Rating | |

| Outdoor | |

| UV Exposure | |

| Adhesive Temperature Range | |

| ASTM D1056 Classification | |

| ASTM D 1056-67 (outdated) | |

| Compression Deflection | |

| Durometer Shore | |

| Density | |

| Tensile Strength | |

| Compression Set | |

| Elongation | |

| UL Rating | |

| Flammability | |

| Application | |

| Industry | |

| Reach / RoHS | |

| Made in: | |

| Test Methods: | |

| Disclaimer a: | Technical data presented above is the foam/material prior to the adheisve. |

| Disclaimer b: | End user is responsible for determining the suitability of the product to application. |

| Terms and Conditions | |

| Sku |

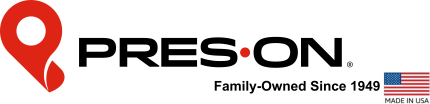

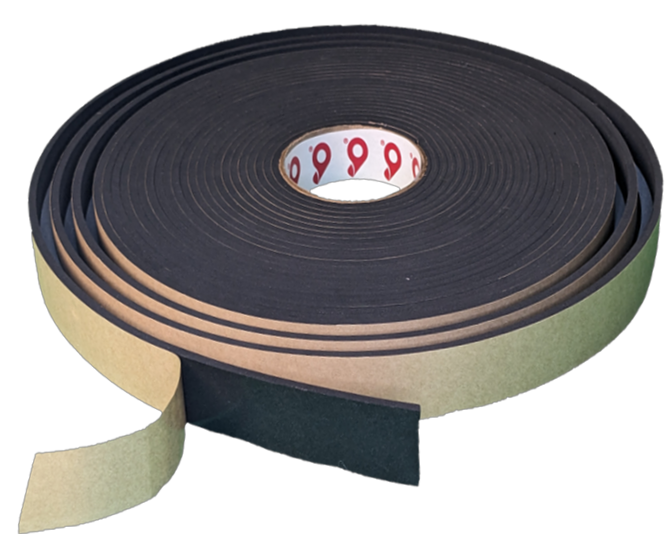

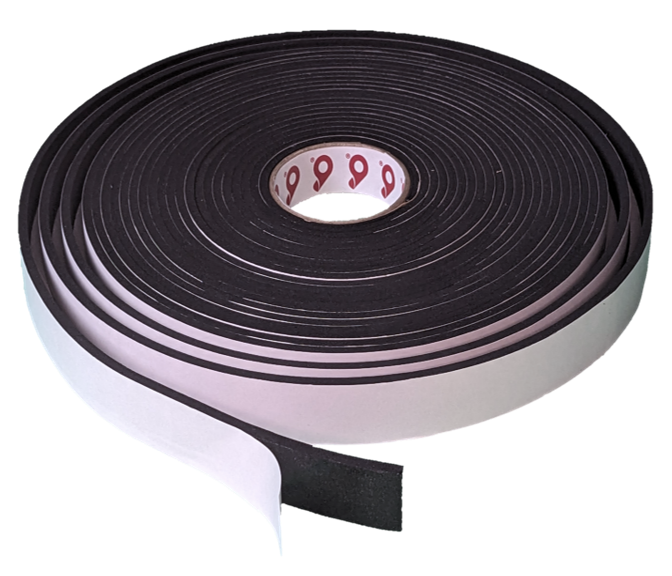

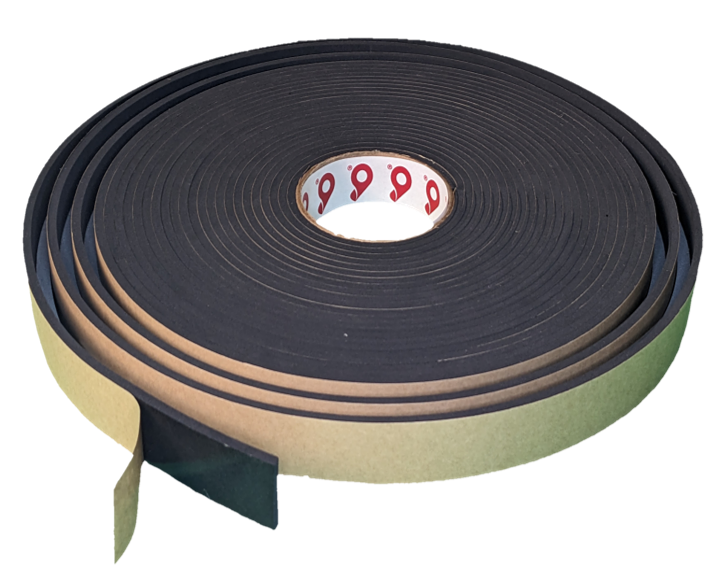

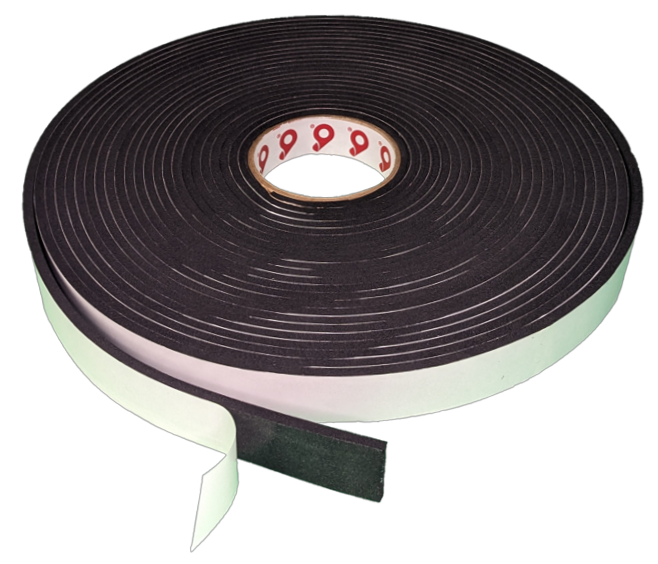

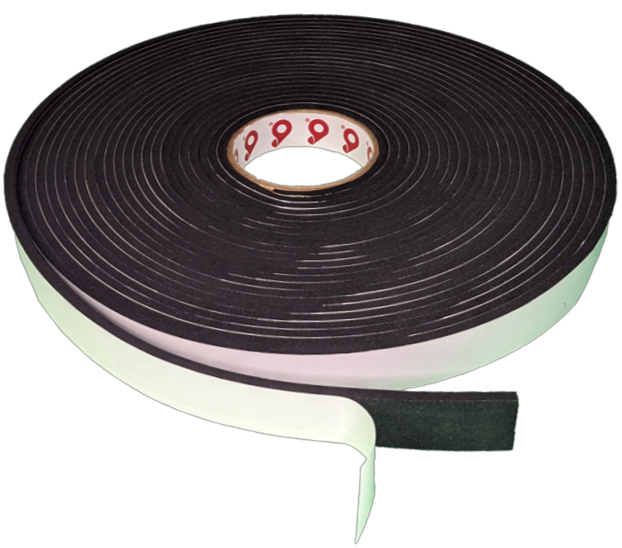

Neoprene Foam Tape – Firm – NE4300

100% Neoprene Foam Tape. Closed cell firm, black, with a smooth surface.

Best quality neoprene foam with an industry leading adhesive bond. Great for most HVAC, enclosure, construction, all gasket applications.

Adhesive: Pres-On’s superior direct wet coat high-tack permanent acrylic pressure sensitive adhesive (PSA) on one side with easy-to-use release liner.

Also available as special order in double sided foam tapes, or plain, without adhesive backing.

Produced in rolls, sheets, pre-cut (digital & die-cut) shapes, spools, and other customizable options.

Learn about “Pres-On’s Superior Wet-Coat Adhesive”

100% Neoprene Foam Tape. Closed cell firm, black, with a smooth surface.

Best quality neoprene foam with an industry leading adhesive bond. Great for most HVAC, enclosure, construction, all gasket applications.

Adhesive: Pres-On’s superior direct wet coat high-tack permanent acrylic pressure sensitive adhesive (PSA) on one side with easy-to-use release liner.

Also available as special order in double sided foam tapes, or plain, without adhesive backing.

Produced in rolls, sheets, pre-cut (digital & die-cut) shapes, spools, and other customizable options.

Learn about “Pres-On’s Superior Wet-Coat Adhesive”

Request For Quote

You may also like…

-

Neoprene Foam Tape – Extra Firm – NE4400

Neoprene Foam Tape. Closed cell extra firm, black, with a smooth surface. Best quality extra firm neoprene foam with an… -

Sponge Rubber Tape – Medium – P8000

Sponge Rubber Foam Tape. Open cell medium, black, with a crisscross surface. Very durable, non-slip, cushioning, textured, rubber foam with… -

Neoprene Foam Tape – Soft – NE4100

100% Neoprene Foam Tape. Closed cell soft, black, with a smooth surface. Best quality neoprene foam with an industry leading… -

EPDM – Medium Foam Tape – P9100

EPDM Foam Tape. Closed cell medium, black, with a smooth surface. Great quality with excellent UV and temperature resistance foam…